The Tasman pulp and paper mill at Kawerau was one of New Zealand’s greatest industrial achievements. It was described by Jack Smith as ‘…the greatest feat in industrial engineering construction in New Zealand,’ and notable because ‘[t]he scale of this project was big by international standards and the paper machine when installed had, at that time, the largest capacity in the world.’

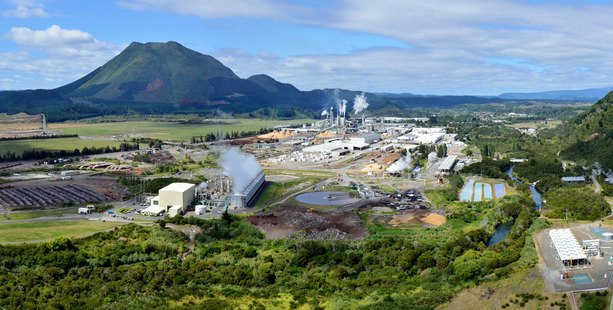

Tasman mill, Kawerau. Photo courtesy Norske Skog Australasia.

From 1925 the pine plantations on the Kaingaroa Plains were the basis of New Zealand’s pulp and paper industries. Early plantings around Waiotapu, using prison labour from 1901 to 1912, were planted at a rate of 300 to 500 acres (120 to 200 hectares) per year. But in 1917 a camp was established for returned servicemen and planting rates increased to an average of 1500 acres (607 hectares) per year. In 1924 the State Forest Service invited British engineering pulp and paper machinery consultants, Walmsleys (Bury) Ltd to advise on uses for the desolate land of the Kaingaroa Plains. They sent William Anderson who recommended large scale plantings of pine trees that could create a pulp and paper industry capable of competing in world markets. State Forest Service Director, Leon MacIntosh Ellis could see that the country would face a timber shortage by the 1960s and proposed a 10 year programme to plant 300,000 acres (121,406 hectares). From 1928 to 1936 up to 1500 unemployed men from the depression years were engaged in planting, in addition to forest service workers. Planting on the scrub land was relatively easy and the rapidly growing radiata pine was easily germinated. By 1935 the Kaingaroa State Forest was 259,147 acres (104,873 hectares), one of the largest man-made forests in the world. It produces the world’s largest wood growth of 23 million cubic feet (622,970 m3) per year.

After extensive testing and trials by the forest service it was determined that New Zealand-grown pine could make pulp equal to that of Canada or Scandinavia. By 1951 the government was ready to offer timber from the Kaingaroa Forest for sale by tender. It was J C Fletcher (later Sir James), second son of the first Sir James Fletcher, who decided that Fletchers should be involved in the pulp and paper industry, even though there was opposition from the government. The only proposal for a pulp and paper mill submitted by the due date in November 1951 was Fletcher’s, with a total estimated cost of £14,800,000 against the New Zealand Forest Service estimate of £13,340,000. The government had offered to contribute £450,000 (15% of the capital) and Fletchers proposed £700,000, leaving £1,850,000 to be raised from public and private investors. The original proposal was for the mill to be built at Te Puke on the Kaituna River rather than the government’s preferred site at Murupara. The government had already let tenders for the earthworks to construct a railway from Edgecumbe to Murupara and it was a condition of the Fletcher contract that the government would construct a new wharf at Mt Maunganui. The government was not happy with the Te Puke site and recommended a new site with geothermal steam near Te Teko, which became Kawerau.

Although there was urgency for the mill to be built because of the maturing Kaingaroa Forest, there were many delays caused by disagreements between the government representatives and Tasman Pulp and Paper Ltd, the new company formed by Fletchers. It was not until July 1953 that the mill site was surveyed and foundation work commenced. The first paper was produced in October 1955, a substantial feat considering the complexity and scale of the plant, which had the largest capacity of any in the world at the time.

There are many complex processes involved:

- Logs arrive by train or logging truck. There are 5 train loads a day from Murupara each with 1,000 tonnes of logs. Logs are unloaded by a large hammerhead crane capable of lifting 30 tonnes of logs at a time. Over 1 million tonnes of logs are handled per year.

- Smaller logs are de-barked by a rotating drum de-barker and larger logs by high pressure water jets. Logs are sorted, some going to the sawmill and others chipped or ground for pulp. Bark is a good fuel when burnt in boilers to produce steam.

- Logs selected for chemical pulp are chipped through a knife chipper and fed to a cooker where chips are reduced to fibres when mixed with NaOH and Na2S heated to 150-165o under pressure. Further processes to screen, wash and bleach are required before the dried pulp is produced.

- Logs selected for mechanical pulp are cut into baulks and ground by massive grinders. Mechanical pulp is treated in a similar way to the chemical pulp and used to make mainly newsprint in the Norske Skog mill.

- The Tasman mill making kraft pulp has a capacity of approximately 300,000 tonnes per annum of bleached and unbleached pulps used by manufacturers of high-quality paper, tissue and building products.

- Tasman’s fibre is predominantly radiata pine and eucalypt. Tasman’s fibre cement pulp is acknowledged in the fibre-cement building products industry as a premium cellulose-reinforcing fibre.

- High white, low coarseness bleached radiata pine kraft pulp is produced from specially selected woodchips. It is produced at the Tasman Mill and designed for use in tissue products where ease of refining and softness are required.

- In 2017 there were three separate paper companies operating at Tasman, two within the original Tasman mill and the third, Asaleo Care nearby in Fletcher Avenue. Norske Skog Tasman Limited operate the mechanical pulp and newsprint mill capable of producing 150,000 tonnes of newsprint per year, 35% of which is used in New Zealand with the remainder being exported to Asia, the Pacific Islands and Australia. Oji Holdings, a Japanese company, bought the pulp mill in 2014, previously owned by Carter Holt Harvey from 2005. Asaleo Care manufactures, markets, distributes and sells essential everyday consumer products using the purchased market pulp.

Ownership changes

The original mill was owned by the Fletcher established company Tasman Pulp and Paper Ltd. In 2000 the mill was sold to Norske Skogindustrier ASA of Norway, and in 2001 it passed ownership of its chemical pulp operations and business on to Carter Holt Harvey Ltd. In 2005 Rank Group Investments Ltd, controlled by New Zealand's richest man, Graeme Hart, took ownership of the Tasman mill along with the Kinleith paper mill.

In 2014 the Tasman, Kinleith and Penrose paper mills were sold to Japanese company Oji Fibre Solutions, one of the largest paper manufacturers in the world. It produces a range of kraft market pulps for use in the manufacture of various papers, boards and specialty products, together with containerboard for conversion into corrugated cases. It services customers globally from three New Zealand paper mills.

Norske Skog retained the operation of the mechanical pulp mill and newsprint mill. The company is a manufacturer and supplier of directory, newsprint, improved newsprint and book paper products to publishers and print media organisations in New Zealand and overseas.

More information

Location

Tasman is located 2 km outside the town of Kawerau, Bay of Plenty, off State Highway 34.

References

Brian Easton, 'Economic history - Industrialisation', Te Ara - the Encyclopedia of New Zealand, accessed 14 Apr 2017.

Jack Smith, No job too hard: a history of Fletcher Construction Volume II: 1940-1965, Wellington, Steele Roberts, 2014.

Michael Roche, 'Exotic forestry,' Te Ara: the Encyclopedia of New Zealand, accessed Nov 2015.

‘Norske Skog Tasman: Kawerau, New Zealand,’ accessed Nov 2015.

‘The Pulp and Paper Industry,’ in ‘Chemical Processes in New Zealand,’ New Zealand Institute of Chemistry, 1998 2nd Ed, section IV, accessed Nov 2015.

‘The Story of Kawerau,’ Te Ao Hou National Library of NZ No 10 April 1955, accessed Nov 2015