5 Jun 2025

With the country’s clean technology sector on the rise, EG speaks to engineers at three companies about their game-changing technologies, and the challenges and opportunities they face.

Aotearoa has long been presented to the rest of the world as a clean, green country: a place of natural abundance, where humans and diverse ecosystems exist in harmony. The reality is somewhat less idyllic, and recent changes to government environmental policy, such as a reversal of the ban on oil and gas exploration, and an increase in mineral mining permits, are viewed as posing a significant risk not only to the climate, but also to the country’s green credentials.

Could clean technology solutions, or cleantech, help get us back on track? Global consulting group BCG thinks so. Its Auckland team recently identified five high-value sectors in which, they say, New Zealand could play a leading role. In number three spot is technology that supports the global energy transition.

This assessment is undoubtedly influenced by the vibrancy of our growing cleantech sector. A 2024 report from the New Zealand Cleantech Mission identified 135 companies working in the sector, with each one tackling challenges as diverse as making fusion energy a reality, to decarbonising concrete. But underlying these success stories is some uncertainty, with the decision to disestablish Callaghan Innovation causing ripples across the cleantech sector.

Reinventing textile recycling

Between 80 and 150 billion items of clothing are now produced each year: that’s more than 10 items for every person on Earth. Worryingly, a growing proportion of these textiles find their way to landfill, releasing greenhouse gases and wasting valuable resources.

Deconstructed textiles used to make StrengthTex pellets. Photo: Jay Drew Photography

Wellington company UsedFULLY is taking a novel approach to tackling this problem. Working in partnership with Scion, it developed a solvent-free process that can turn textile waste into high-value materials. And the team is turning their attention to a global market.

“Textile waste is a material science issue,” says engineer Deborah Crowe, Business Strategist at UsedFULLY.

“People get caught up in the idea that circularity means a product needs to be turned back into itself. We go down to the raw resources, then use those to make something new. The solution is not always a closed loop, it can be a spiral.”

The fibres within consumer textiles are typically cellulose (for example, cotton), petroleum-based (polyester) or proteins (wool), with many textiles using a mix of fibres. UsedFULLY’s technology was initially developed by Scion to recover cellulose from waste timber. It can now process blended fibres, and produce materials ready for use in roading or construction projects.

“New Zealand imports a cellulose fibre from Europe as an asphalt additive for our roads,” says Deborah.

Successful lab tests replacing that cellulose with fibres produced from waste cotton t-shirts led to a real-world roading trial. A small section of The Terrace in Wellington was successfully resurfaced, incorporating the UsedFULLY product.

“And we’ve since discovered that polycotton fibres perform just as well as cotton, sometimes better. It’s exciting because polycotton is probably our largest waste stream.”

Despite this success, Deborah admits that UsedFULLY has had to pivot several times in response to changing – and challenging – economic environments.

“It takes a lot of capex to get cleantech solutions up and running, and that’s proven to be really difficult in New Zealand. We’ve had to accept that our first plant is not going to be built here.”

Instead, they’ve exclusively licensed their technology with Scion, and are looking to Europe and Australia, where textile recycling is not a niche idea, but a mature one that’s having real impact. “It’s one thing to have the technology,” says Deborah. “You need the market forces and policy drivers too. That’s not currently the case here, so we have to be pragmatic and go where the pull is.”

Making critical minerals with no mining waste

Another innovative cleantech company turning waste into value is Aspiring Materials. From its base in Christchurch, it produces multiple critical minerals and essential materials from one commonplace rock, leaving no harmful waste behind.

“We start with magnesium silicate-based rocks like olivine, and digest it in acid to turn it into a sort of elemental soup,” says Lead Chemical Engineer Dr Megan Danczyk. “Then we extract each of the elements as individual products.”

Dr Megan Danczyk with a scoop of magnesium hydroxide fresh off the pilot plant. Photo: Aspiring Materials

The products they extract have numerous industrial applications. For example, silica can be a partial replacement for Portland cement, and magnesium is used in everything from wastewater treatment to alloy manufacturing. Their nickel and cobalt products, which Megan admits were “challenging” to successfully extract from the rock, could find use in high-performance batteries, plus “a few other exciting things that we’re currently working on as R&D”.

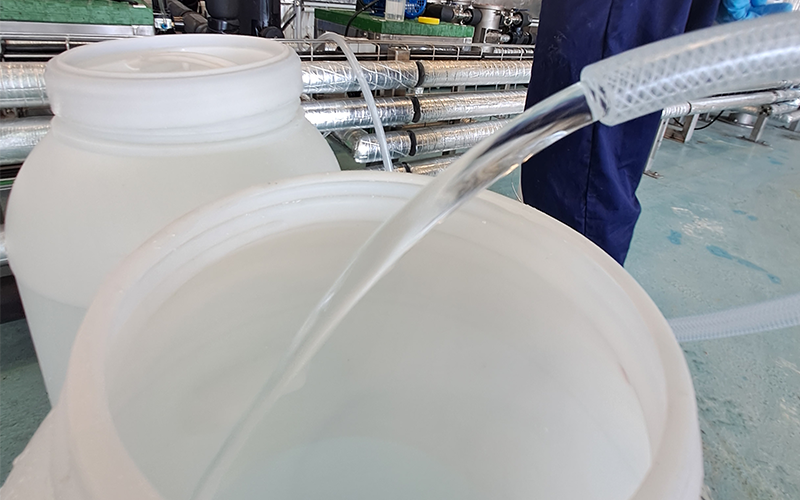

At the end of the extraction process, what remains is a salty brine. This, Megan explains, “… goes to an electrolyser, which recycles and regenerates the acid we use for digestion and the base we use to separate the products”. This makes Aspiring Materials’ process a closed loop. “Unlike other mineral extraction processes, we’re using the whole rock.”

Olivine can be widely found across the globe in the upper part of the Earth’s crust, making it easily accessible. And it also exists above the ground, as piles of overburden on existing mining sites.

Olivine-rich rock is found in abundance throughout the world and is currently used as roading aggregate in New Zealand. Photo: Gareth Moon Ethik Studios

In March, Aspiring Materials opened its first pilot plant in Bromley, Christchurch, and is already operating according to plan. At full capacity, it will process 250kg of olivine per day, producing industrial-grade magnesium, nickel-cobalt-manganese hydroxides and silica.

“Stage two of the pilot plant build will add on our recycle loop,” Megan explains. This will enable the production of green hydrogen, which could be used to reduce the carbon footprint of New Zealand-made fertilisers, or to produce cleaner shipping fuels.

“In a lot of places, it is mining waste that we can process and turn into valuable, high-purity products,” says Megan.

The only “waste” from Aspiring Materials’ process is a salty brine which is regenerated back into the mineral extraction process, closing the loop on the materials used. Photo: Aspiring Materials

In a lot of places, it is mining waste that we can process and turn into valuable, high-purity products.

The olivine is being sourced from the largest olivine producer in the United States, who Megan says produces it in huge quantities in a fine flour form.

“It’s high purity feedstock, but kind of a waste product for them.”

In the medium term, Aspiring Materials plans to expand to the States, with the first commercial plant in Washington State.

“We’re definitely keeping our R&D here in New Zealand,” she says, “and we think it’s also an excellent place to expand the business – we have port access, clean energy and feedstock. But it’s all dependent on funding.”

Forging the coolest fuels for future transport

On the other side of Ōtautahi Christchurch, you’ll find a cool cleantech company – Fabrum. Established in 2004, and home to more than 30 engineers, Fabrum develops game-changing cryogenic technologies and advanced composites that make it possible to produce and store gases such as hydrogen, nitrogen and oxygen at such low temperatures, they become liquids.

“Fabrum started as a composites business,” says Chief Technology Officer Dr Neil Glasson CMEngNZ CPEng IntPE(NZ). The founders, working on superconductivity research, needed to store liquid nitrogen coolant, and requirements were tight.

“Making containment that is non-conductive, that survives the cold without breaking, and holds a vacuum for a long time is a challenging task. They managed to devise a composite that could do all that, and used it to make containers.”

What began as a scientific endeavour “… really matured into our product offering now”, Neil says.

“That capability is perfectly positioned for producing lightweight liquid hydrogen storage.”

The cryogenic technology came later, around 2014.

“Industrial Research Limited was working on advanced cryocoolers,” says Neil, who spent several years there.

“They patented it and then it came to Fabrum for commercialisation.”

Fabrum’s PTC1000 Cryocooler. Photo: Fabrum

Today, Fabrum’s cryocooler customers are scattered around the world, spanning a range of industries including medicine, aerospace, food and sustainable energy.

Neil, who oversees the company’s research and development, describes its work on hydrogen storage as “quite world beating”.

“The current technology is to use a metallic tank, because that’s better understood. But the main metric for anything aviation-related is weight. Only composite tanks can give you that lightweighting.” He says Fabrum is working with various aviation startups looking to carry hydrogen fuel on-board.

Alongside this, the company has developed a hydrogen reliquefier that can be retrofitted onto liquid hydrogen storage facilities, and capture the boil-off gas.

“This is a world-first,” says Neil. “When you store liquid hydrogen, you have to vent some gas to maintain pressure. You might be venting up to 1 percent of the product per day. For large facilities, that loss becomes expensive.”

Fabrum is currently working with a customer in the United States who plans to install this system onto hundreds of their storage tanks. Before that can happen, the reliquefier will undergo factory acceptance tests with the customer present. For that, the team will use a unique containerised hydrogen testing facility that they built and unveiled at Christchurch Airport in February.

Reliquifier container at Fabrum’s hydrogen test site. Photo: Fabrum

“Short term, our goal is to keep knocking our projects out of the park. Long term, we want to see our technology licensed and used more broadly. We’re a long way from most of our markets. So, if we want to scale our technology and make an impact on climate change, we’ll need to expand beyond New Zealand.”

In the 2024 Cleantech report, authors identified three major challenges facing New Zealand’s cleantech ecosystem: lack of investment, disconnect from international markets and need for collective growth. As these three cleantech companies show, such concerns are widely experienced across the sector. If we’re to truly be at the forefront of cleantech, those challenges will need to be overcome.

This article was first published in the June 2025 issue of EG magazine.