18 Apr 2023

Aotearoa generates an estimated 17.49 million tonnes of waste annually. Around 12.59 million tonnes of this goes to landfill, according to data from the Ministry for the Environment, posing a risk to people’s health and the environment. But the efforts of clever engineers – and engineering – aren’t being wasted.

The Government is aiding the transition to a low-emissions circular economy through its waste work programme, proposing a new waste strategy and more comprehensive waste legislation, as well as investing in waste reduction schemes. Meanwhile, initiatives such as the Zero Waste Network, representing community enterprises across the country who are working towards zero waste, aim to minimise and ultimately eliminate waste, forging a path toward a zero-waste country. Beyond government intervention and citizen action, engineers are also rising to the challenge.

Shaping a circular plastics economy

In 2021, Aotearoa sent more than 300,000 tonnes of plastic to landfills. That’s a significant amount of waste – one that an interdisciplinary team from the University of Auckland’s Faculty of Engineering and Business School and the RMIT University in Melbourne intends to reduce through a circular market system for plastics. The five-year project was awarded an $11.7 million grant from the Ministry of Business, Innovation and Employment's 2022 Endeavour Fund.

“We’re aiming to work towards New Zealand’s goal to be less reliant on virgin plastics and also reduce carbon emissions because if we recycle plastics more, we’re emitting less carbon dioxide,” said Dr Johan Verbeek CMEngNZ, Professor of Mechanical Engineering at the University of Auckland and Co-Director of the University's Centre for Advanced Materials, Manufacturing and Design.

Johan and Professor Simon Bickerton of the Faculty of Engineering are investigating how to take waste plastic and process it in a way that would produce better materials and keep it within a circular economy.

“We are researching how to use plasma to modify the properties of polymers, making it possible for us to recycle more materials in a cheap and environmentally friendly way. An example would be if you have a mixture of two or three plastics that’s difficult to separate. We’ll look at how we can use this plasma technology to make a blend that is so good that it can be used instead of virgin materials,” Johan says.

“That way, we can keep plastics in the circular economy for longer. It’s about how we apply material science and design into developing better products and better materials for those products.”

Meanwhile, Associate Professor Julia Fehrer of the Business School and colleagues from RMIT University will design digital tools and develop a digital infrastructure to enable businesses to participate and operate in a circular economy for plastics.

“It’s also about how to get businesses to adapt to, and actively engage in, a circular market,” says Johan.

The project is underway but is still in the initial stages of research, with the team actively recruiting students and staff with a background in mechanical engineering, chemical engineering or materials engineering.

“Because it’s such a transdisciplinary project, these people need to have design skills and practical material science skills, but also be able to understand how to apply materials in making products,” Johan says.

By creating a circular market system for plastics, Johan hopes to contribute to a zero-waste nation.

“Success would be if we can actually reduce the amount of plastic that goes to landfill.”

From food waste to energy

Compared to plastics, food waste comprises an even bigger part – more than 333,000 tonnes – of waste sent to landfills. In Auckland alone, an estimated 100,000 tonnes of domestic food scraps go to landfill every year. But that’s about to change.

“Auckland has a vision of zero waste to landfill by 2040,” says Parul Sood, General Manager Waste Solutions at Auckland Council.

“As part of that vision and the journey toward zero waste, we’re getting food scraps out of the rubbish bin and into a facility for processing.”

This facility is the Ecogas Reporoa Organics Processing Facility, in the central North Island, which will use anaerobic digestion – wherein bacteria break down waste in the absence of oxygen – to convert 75,000 tonnes of organic material into energy and bio-fertiliser.

“The anaerobic digestion plant will help us divert about 50,000 tonnes of organic material to start with from landfill, and everything that comes out of the plant will have beneficial reuse,” Parul says. She adds that the facility is the first and largest of its kind in the country dealing with kerbside food scraps.

Success would be if we can actually reduce the amount of plastic that goes to landfill.

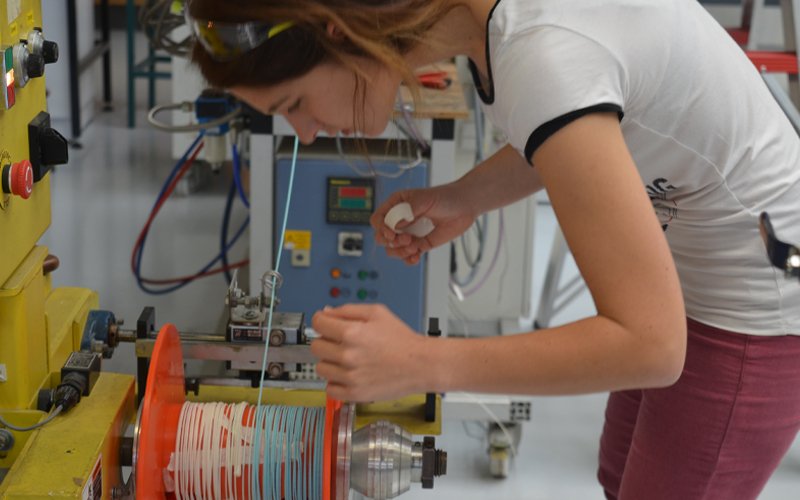

Student processes plastics material into drawn filaments. Photo: University of Auckland

Local governments like Auckland Council face a number of challenges as they try to achieve zero waste.

“Waste is a systems problem and councils are normally at the bottom of that system,” says Parul. While producers manufacture products, consumers use those products and then waste gets generated, which is where councils come in to provide waste management services.

“It’s a challenge for local governments as we are one stakeholder, but we have to work with the system,” Parul says.

“We need support from the central government to make sure the legislation and rules are right so that producers and consumers do the right thing. For our part, we advocate for best practices so that the policies set in place are workable. All of us need to work together to change the system.”

Engineers also have a vital purpose in helping councils attain their zero-waste goals.

“Thinking beyond what we’ve got is what we would look to the engineering community to give us,” says Parul.

“Their innovation and scientific knowledge is so crucial, and being open-minded about solutions is critical as well.”

Parul Sood, General Manager Waste Solutions at Auckland Council. Photo: Auckland Council

Designing the landfills of tomorrow

Landfills are an essential part of waste management. What started as open dumping progressed into controlled tipping with some protection measures in place, then evolved into sanitary landfilling where waste is disposed under highly controlled conditions.

According to Dr Sean Finnigan CMEngNZ IntPE(NZ), Director of Environmental Engineering at engineering firm Fraser Thomas, changes in landfill design and operations have been prompted by more stringent regulations and consenting requirements, developments in landfilling practice, and increasing environmental awareness and public expectations.

“Good landfill design now is a multidisciplinary approach involving different fields of engineering, including geotechnical, civil and environmental, and supporting disciplines such as structural, electrical and mechanical for plants and structures,” says Sean.

He cites the North Waikato Landfill, also called the Hampton PARRC (Power and Resource Recovery Centre), as an example of good landfill design. Located at Hampton Downs and built on more than 380 hectares of former farmland, the facility began operating in 2005 and is consented to dispose of 30 million m3 of refuse.

“It’s engineered to modern landfill standards,” Sean says, which includes a fully engineered containment system; a full leachate drainage, extraction and removal system; a full landfill gas control, extraction and monitoring system with landfill gas used to produce electricity; and an engineered final capping system to contain the waste materials, minimise rainfall infiltration which generates leachate and restores the land to productive agricultural use.

As long as people generate waste, landfills will continue to play a role in managing waste.

“The unfortunate reality is that the modern New Zealand lifestyle produces a lot of waste, of which a significant portion still ends up in landfill,” says Sean.

“If we have to create new landfills, then they need to be modern, engineered facilities designed to a very high standard so as to minimise potential adverse effects on human health and the environment.”

Site selection is a critical first step when building new landfills, as evidenced by the Fox River landfill disaster of 2019 on the West Coast, where flooding exposed an old landfill on the riverbank, washing thousands of kilograms of rubbish out to sea.

“Avoid natural hazard areas, such as sites located adjacent to rivers or coasts or on significant overland flow paths or floodplains, and sites with significant geotechnical constraints or on fault lines,” says Sean.

Another consideration is PFAS (per- and polyfluoroalkyl substances), manufactured chemicals found in everyday products such as cosmetics, non-stick cookware and stain-resistant fabrics.

“PFAS have been called the ‘forever chemicals’ because they do not break down in the environment,” Sean says.

“Future landfill design may need to consider providing dedicated cells for known PFAS-containing wastes and for appropriate management and disposal of leachate with low-level PFAS contamination.”

Most importantly, however, engineers must incorporate sustainability when designing new landfills.

“Assess climate change effects, including risks from rainfall increases, more intense floods, sea level rise, river scour and coastal erosion.”

Sean continues: “Maximise landfill gas capture and collection – mainly carbon dioxide and methane – and use it to generate electricity or destroy it to stop it from entering the atmosphere and contributing to greenhouse gas emissions.”

Ecogas Reporoa Organics Processing Facility will convert organic material into energy and bio-fertiliser. Photo: Ecogas

Better alternatives to landfills are emerging, and engineers are at the forefront of these innovations.

“Most of the alternatives to creating new landfills are based on the diversion of relevant waste materials to other uses,” Sean says.

“Key to this is sorting waste materials into different categories and minimising cross-contamination.”

For instance, electrical, mechanical and software engineers at green tech startup ARCUBED developed OneBin, an AI-powered recycling bin that recognises and sorts waste at the point of collection to reduce contamination. Meanwhile, digital platform CiRCLR, cofounded by a software engineer, connects businesses with other businesses that can use their waste as a resource, thereby reducing the amount of waste going to landfill.

Sean says “As an environmental engineer, I fully support moves toward a circular economy and the 3Rs – reduce, reuse, recycle – with disposal to landfill being the least preferred option of the waste hierarchy.

This article was first published in the March 2023 issue of EG magazine.