13 Jan 2026

In a world increasingly menaced by hotter, drier conditions, with a trend towards denser housing, the way we deal with fire is changing – and the work of engineers is proving crucial.

In August, the Government announced that it will change the Building Code to strengthen fire safety requirements, prompted by a nationwide review following the deadly 2023 Loafers Lodge fire. Also this year, BRANZ unveiled a new lab in Porirua offering some of the most advanced fire-testing capabilities in the Southern Hemisphere. Meanwhile, innovative New Zealand-based firms are doing their part to develop the vehicles and equipment needed to take on the mega fires experienced in Australia, California and elsewhere. Kiwi fire engineers are heavily involved in these developments. The expertise of these engineers was only formally recognised in New Zealand as an independent discipline in the early 1990s with the introduction of performance-based design and the establishment of dedicated university training. So, what exactly do they add to fire safety?

The new BRANZ fire testing facility in Porirua. Photo: BRANZ

Getting “the right mix of safety features”

Greg North CMEngNZ CPEng IntPE(NZ), immediate past-President of the Society of Fire Protection Engineers (SFPE) NZ, says fire engineers are involved in diverse sectors, including insurance, policy setting and the fire service itself, but most work in the built environment. Whereas architects and other design engineers typically focus on construction elements and system components, fire engineers are more of a strategic and holistic design profession, Greg says.

“We look at performance, and our focus is more on getting the right mix of features in a building to provide an appropriate level of safety.”

He says that could be to meet the minimum Building Code, but it could involve satisfying the specific requirements of a client such as business continuity, property protection or insurance risk mitigation.

“In some ways we’re like an acoustic engineer who starts with how much noise attenuation is appropriate to a room, and the building design features flow from that decision.

“In a similar way, we work with the architect, client and others to determine the best way to develop a suitable level of fire safety within and around the building. We then work with the design team to help them develop the specific built features that can deliver this level of safety.”

We look at performance, and our focus is more on getting the right mix of features in a building to provide an appropriate level of safety.

Anusha Chevutu (print board assembler) tests heat detectors. Photo: Mark Tantrum

Like many European nations, as well as Australia, New Zealand fire engineering operates in a legislative regime with a performance-based focus, Greg says, while other countries are more prescriptive. Another point of difference is our historical penchant for timber. Also, earthquake resilience is a major concern here.

“Our buildings have to perform in a seismic event, where specific consideration is sometimes needed for how buildings will move and how our fire safety features will move. There’s also sometimes a difference in the way we develop our fire strategies. A fire designer can choose whether to rely more on the physical construction of buildings, the passive fire features, or lean more towards active features such as sprinklers and alarm systems. In New Zealand, we have a pretty good balance between relying on both.”

But we can do better, Greg adds, and there’s always a need to evolve. For instance, the SFPE is currently working on the issue of electric vehicle fire risks.

“There’s a group of fire safety professionals, including members of the SFPE, who are looking at developing New Zealand-applicable guidelines for EVs, along with Engineering New Zealand. What’s the real risk? Is it too high? What strategy should we take in our buildings for EVs? And so on.”

In the same vein, Engineering New Zealand Practice Note 22, which was released in 2011 to improve collaboration between design professionals and to streamline fire design documentation, has recently been changed. Tellingly, while the revision clarifies the roles and obligations within a design team, the strong emphasis throughout is that fire design coordination has to be a shared responsibility. Ultimately, the goal is to make better, safer buildings.

Advancing fire safety technologies

But what about when the worst happens and a fire breaks out? Since 1986, when his Lower Hutt business Pertronic launched its first automatic fire alarm control panel, that question has preoccupied David Percy ONZM FEngNZ. He was recognised in the 2025 King’s Birthday Honours for services to fire safety technologies, as well as to business and the community. As a member of a number of New Zealand Fire Alarm Standards committees over the years, he played a role in potentially life-saving developments, including the requirement since 2003 that all fire evacuation alarms have a voice announcement to go with the alarm sound.

“New Zealand was one of the first countries to require that,” he says. “It makes it completely unambiguous.”

Pertronic compliance engineer Daniel de Waal carries out internal testing on an F220 fire panel. Photo: Mark Tantrum

Pertronic’s work to improve automatic fire detection and alarm systems has been even more influential. When the company, which employs 30-odd engineers among its 160-strong staff, was founded in the early 1980s, it had half-a-dozen domestic competitors. Today, it’s the sole surviving New Zealand-based manufacturer in the field. Its systems are used throughout New Zealand in everything from small commerical buildings to big, and complex facilities, and it exports compatible products to markets in Southeast Asia, the Pacific, Australia and the United States. One reason for that success is Pertronic’s policy of reinvesting at least 17 percent of annual gross revenue in research and development, which has enabled it to keep abreast of technological developments.

There have been a few.

“The equipment has become a lot smarter,” David says, noting that the early fire alarm control panels were relatively simple relay-based systems.

“The technology then moved to electronic panels using integrated circuits, then to microprocessors, which enable control panels to do all sorts of things. They can shut down air conditioning, for instance, or redirect it so you don’t blow smoke from one area into another.

“Modern panels also have extensive logging facilities, so if there’s been a fire you can download the log to see what happened.”

That same theme of growing sophistication also applies to the world of fire-fighting machinery. Take Lower Hutt-based Fraser Engineering, for example, which produces fire appliances that are tailored to the particular demands of fighting bush fires in Australia.

“Because we’re a production engineering and design shop, as well as a fire appliance manufacturer, we design all our equipment in an ongoing feedback loop with our customers,” says General Manager Martin Simpson.

“We take into account things like climate, terrain, roads.”

The fact that many firefighters are volunteers, with diverse body types, is also a consideration.

“You have to be flexible and make it easier for these guys to get equipment out at different heights, and to ensure systems are as light as possible.”

Fraser Engineering’s patented breathing apparatus seats enable firefighters to travel to the scene safely and in comfort. Photo: Mark Tantrum

Fraser Engineering’s business has grown rapidly. Recently, it was awarded an $80-million, five-year contract to provide fire appliances to Queensland. It’s in the throes of doubling production capacity, including building a factory in Brisbane, and is taking on at least 50 new staff. That’s partly the result of the increasing frequency and ferocity of bush fires, but it’s also a vote of confidence in the company’s commitment to safety and constant improvement.

“All our development is about crew protection. The appliances come with deluge systems around the windows, to prevent thermal shock. We have drop-down curtains inside the cab in case windows blow out, and something like a scuba emergency system to provide air for 15 minutes if crew get into real trouble. All the tyres have water sprays so they don’t catch on fire; there are under-truck sprays, and flame-proof lagging on any system that could potentially stop the truck running. We’ve even developed safety locking mechanisms so the crew can’t lock it inadvertently.”

There’ll be more changes to come.

“It’s about things like trying to get more water onboard, coming up with smarter ways to design vehicles – things are always evolving.”

Fire Engineering class

Work is underway to launch a new CPEng Fire Engineering class in mid 2026. It will clarify competency expectations for engineers, improve the consistency of Fire Engineering standards nationwide, and provide greater assurance for BCAs and the public. Only those working in the Fire Engineering space will be affected. Transition arrangements will be published once the class is established for those CPEng wishing to be recognised in the Fire Class.

It’s about saving lives

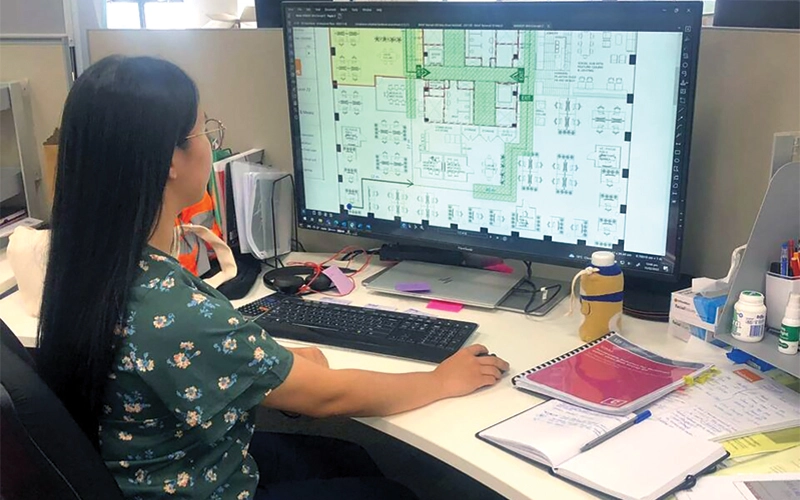

In her final year of civil engineering at the University of Canterbury, Stella Liu took an introductory course on fire engineering, not knowing exactly what was involved.

“It touched on every area: human behaviour, fire protection systems, how different materials react in fires… At the time, that just seemed so interesting and so different.”

Photo: Supplied

She was hooked. After completing a final research project in the structural fire engineering area, Stella joined GHD 18 months ago as a graduate fire engineer, while also studying for a Master of Fire Engineering Studies. Her job entails everything from writing fire reports, drawing fire safety sketches and issuing passive fire safety specifications, to helping with fire safety design. Her latest project involves detailed design and construction monitoring on the University of Canterbury’s new accommodation hall.

Ultimately, fire engineering is about saving lives.

“Our main objective is to make sure that people come out of a fire safely and that it doesn’t spread to neighbouring buildings, and to support fire-fighting operations.”

This article was first published in the December 2025 issue of EG magazine.